Mining

A trusted solution for ANY organisation looking to improve risk management, increase innovationand make meaningful data-driven decisions.

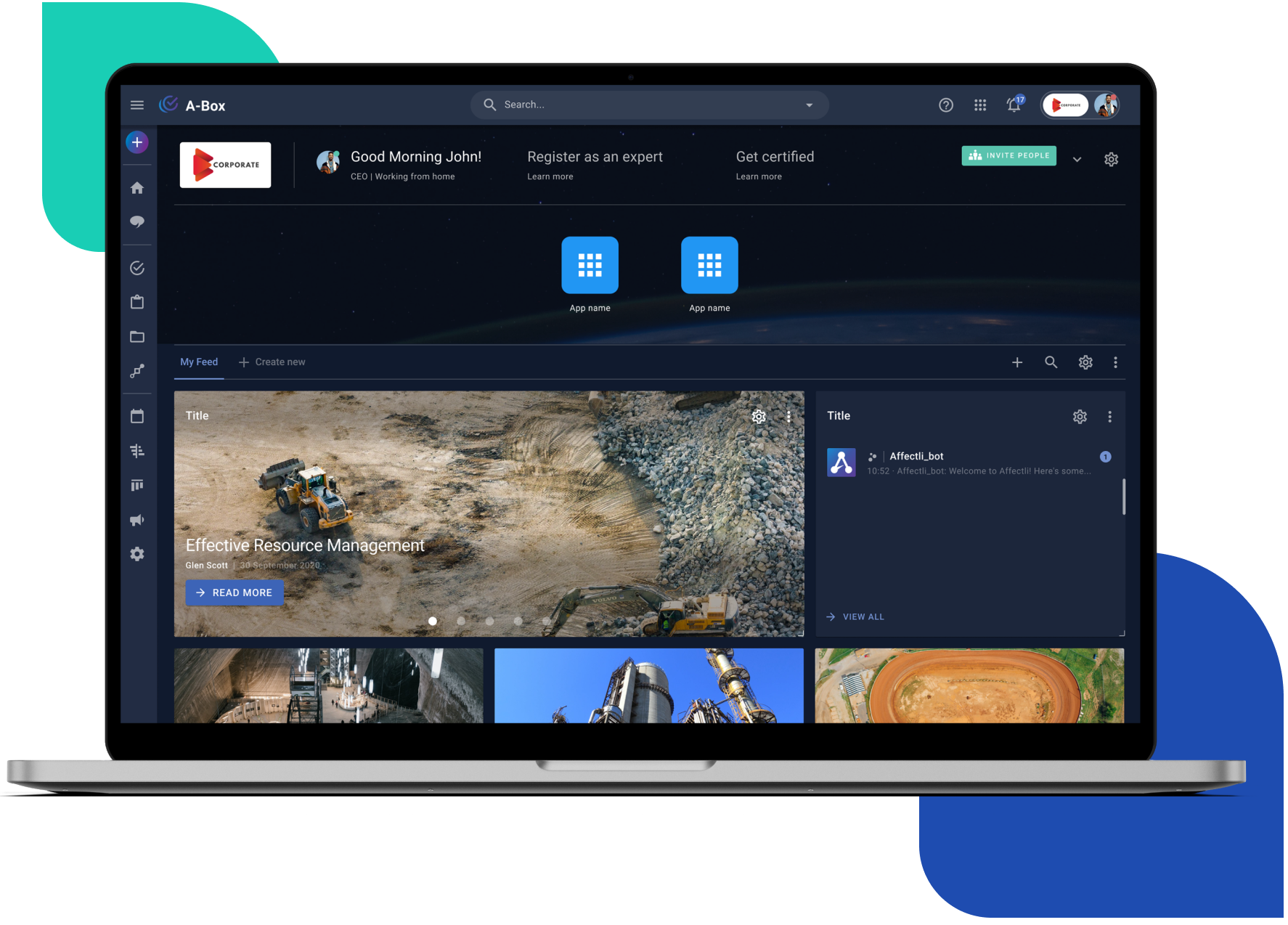

Affectli for mining

ABOUT THE COMPANY

The Challenge

Added to the challenges of managing such a remote location, our client was looking to consolidate critical information to drive informed decision making, mitigate risk and improve labour & equipment efficiencies.

The Solution

Provide the client with the ability to:

- Improve security; safety and mitigate risk.

- Consolidate multiple sources of data from a plethora of disparate systems and equipment into a single control room.

- Provide meaningful, real-time data to drive informed decision making.

- Provide meaningful, real-time contextual data that is dispatched to the right people at the right time.

- Effectively manage people, equipment and components within the organisation.

- Maximise efficiencies through the ability to convert labour-product and equipment-product productivities in real-time.

- Real-time monitoring and factoring of geological conditions; operating time & delays; declining ore quality; equipment and purchasing of consumables.

- Calculate and predict productivity.

- Visualise actual production vs. budget in real-time through a single dashboard.

- Pinpoint where in the value chain ore has gone missing.

- Real-time audit trails, reporting and super analytics available at the click of a button.

THE AFFECTLI ORCHESTRATION

The integration included various subsystems such as conveyor belt weightometers, plant SCADA, drone technology, weighbridge, and geo-fencing that work in conjunction with CCTV live feeds and vehicle tracking devices. The powerful MI-STREAM processor then ingests all the data from these multiple points, which is then transformed into meaningful, contextual data that is viewed on a single dashboard in real-time.

The multiple live CCTV feeds are folded into the GIS infrastructure of the AFFECTLI system, allowing the control room to view remotely, as well as locate assets on maps. Through an ontological approach, these assets can then be drilled down into granular detail that includes the likes of blueprints and technical drawings – all with the ease of clicking a button.